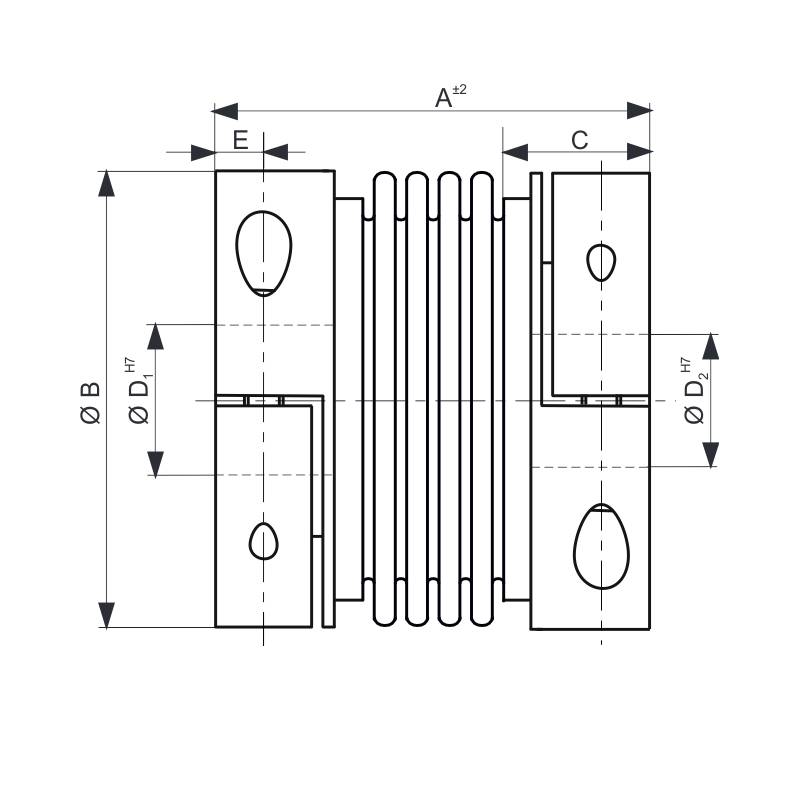

Metal Bellow Coupling – Model CTB-2

with clamping hubs

- small installation space

- low moment of inertia

- easy to install

- wear and maintenance free

- hub material Series 2 - 150: aluminum

- hub material Series 150 - 1500: steel

- bellows: stainless steel

- special designs such as welded versions or stainless steel on request

| properties | unit of measurement | unit symbol | 2 | 5 | 10 | 15 | 30 | 60 | 150 | 300 | 500 | 800 | 1500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rated torque | (Nm) | TKN | 2 | 5 | 10 | 15 | 30 | 60 | 150 | 300 | 500 | 800 | 1500 |

| overall length | (mm) | A±2 | 34 | 39 | 42 | 50 | 46 | 56 | 59 | 66 | 70 | 78 | 79 | 89 | 92 | 103 | 113 | 126 | 118 | 133 | 141 | 167 |

| outside diameter | (mm) | B | 24,5 | 32 | 40 | 49 | 56 | 66 | 81 | 110 | 124 | 132 | 157 |

| clamping fit length | (mm) | C | 12 | 14 | 14 | 22 | 27 | 29 | 34 | 43 | 43 | 35 | 45 |

| inner-Ø H7 | (mm) | D1/2 | 4 - 12 | 6-16 | 6-24 | 8-28 | 10-32 | 14-35 | 19-40 | 25-60 | 35-62 | 40-75 | 50-80 |

| distance | (mm) | E | 4 | 5 | 5 | 8 | 8 | 11 | 12 | 15 | 15,5 | 17,5 | 22,5 |

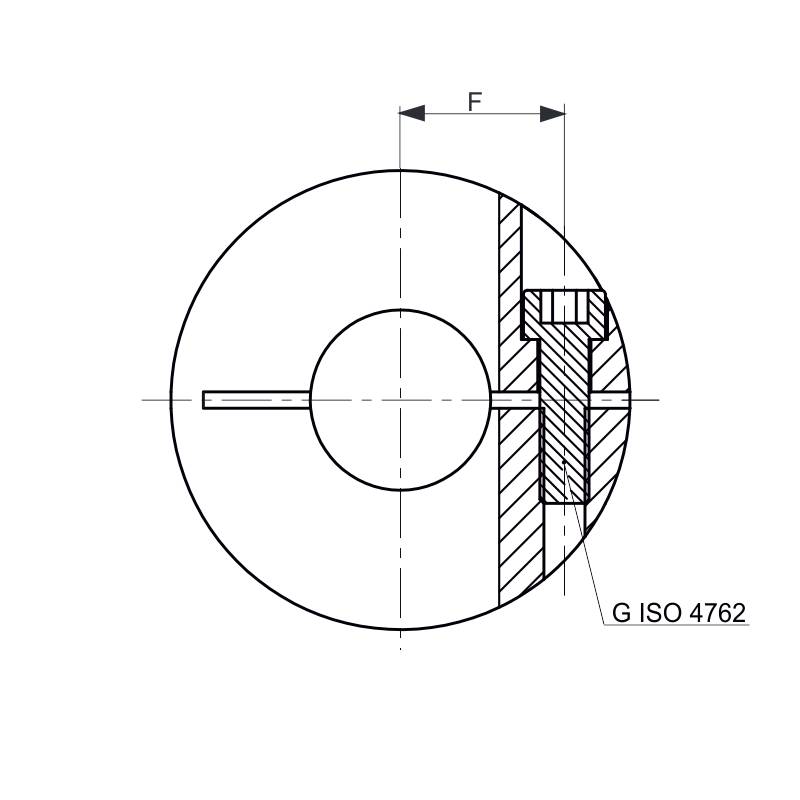

| distance | (mm) | F | 8 | 11 | 15 | 18 | 20 | 24 | 27 | 40 | 43,5 | 48 | 55 |

| fastening screws | G | M3 | M4 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | 4 x M16 | 4 x M20 | |

| tightening torque | (Nm) | G | 2 | 4 | 4 | 8,5 | 15 | 35 | 70 | 120 | 200 | 250 | 470 |

| moment of intertia | (10-3kgm2) | Jges | 0,002 | 0,003 | 0,01 | 0,02 | 0,02 | 0,03 | 0,06 | 0,07 | 0,13 | 0,14 | 0,27 | 0,3 | 2,2 / 0,75 | 2,3 / 0,8 | 8,9 | 9,1 | 14,7 | 14,9 | 16,5 | 40 |

| approximate weight | (kg) | 0,03 | 0,06 | 0,1 | 0,2 | 0,4 | 0,6 | 2,4 / 1 | 5 | 6 | 8,5 | 14,5 | |

| CT-B2-24-01 |

Bellows glued up to series 500 and welded as half-shell version from series 800.

| properties | unit of measurement | 2 | 5 | 10 | 15 | 30 | 60 | 150 | 300 | 500 | 800 | 1500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| number of waves | 4 | 7 | 5 | 8 | 5 | 8 | 4 | 6 | 4 | 6 | 4 | 6 | 4 | 6 | 4 | 6 | 4 | 6 | 6 | 5 | |

| torsional stiffness approx. | (103 Nm/rad) | 1,3 | 1,3 | 7 | 6 | 8 | 7 | 22 | 22 | 39 | 35 | 93 | 53 | 177 | 107 | 535 | 405 | 400 | 300 | 480 | 1215 |

| spring stiffness axial approx. | (N/mm) | 14 | 25 | 40 | 29 | 33 | 55 | 38 | 18 | 52 | 32 | 76 | 52 | 86 | 65 | 112 | 74 | 72 | 48 | 110 | 322 |

| spring stiffness lateral approx. | (N/mm) | 170 | 95 | 200 | 108 | 355 | 130 | 460 | 137 | 1435 | 215 | 1400 | 260 | 1620 | 350 | 3860 | 1140 | 3010 | 840 | 2000 | 3600 |

| axial misalignment | (mm ±) | 0,5 | 0,5 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 2 | 1,5 | 2,0 | 2 | 3 | 2,5 | 3,5 | 2,5 | 3,5 | 3,5 | 3,5 |

| lateral misalignment | (mm ±) | 0,15 | 0,2 | 0,20 | 0,30 | 0,20 | 0,30 | 0,15 | 0,20 | 0,2 | 0,2 | 0,20 | 0,25 | 0,20 | 0,25 | 0,25 | 0,30 | 0,30 | 0,35 | 0,35 | 0,35 |

| angular misalignment | (°) | 1 | 1,5 | 1,5 | 2 | 2 | 2 | 1,0 | 1,5 | 1,0 | 1,5 | 1,0 | 1,5 | 1,0 | 1,5 | 1,0 | 1,5 | 1,0 | 1,5 | 1,5 | 1,5 |

Temperature range : -30°C to +100°C